A PVC-free inflatable future.

Say goodbye to the days of cheap plastic pool floats and join us in our commitment to floating PVC free.

Over the past few decades, polyvinyl chloride (PVC) plastic, commonly known as the ‘poison plastic’ has become one of the most widely-used types of plastics. We find it all around us, especially, with cheap, inflatable pool floats currently on the market. Its advantages are that it is versatile and inexpensive. However, the price we pay for a low-cost and seemingly harmless PVC donut or flamingo for our pool this summer is far steeper than it may at first appear.

In fact, this commonplace plastic is one of the biggest contributors to the flood of toxic substances saturating our planet. PVC contaminates the environment throughout its lifecycle; during its production, use and disposal. While most plastics pose threats to the environment, few consumers realise that PVC is one of the single most environmentally damaging of all plastics.

The Alternative, Thermal Polyurethane (TPU)

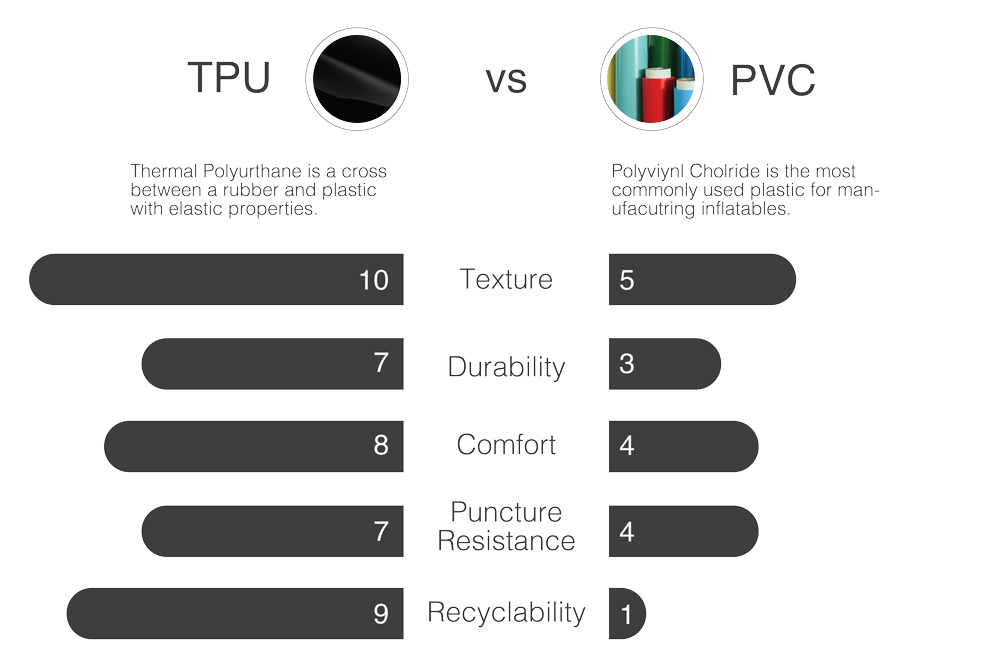

We do our best to ensure our products are as environmentally friendly as possible. We do so by using a material called thermal polyurethane (TPU) to make our inflatable cores, which in essence is similar to a thin rubber film. Despite being very expensive TPU is an extremely recyclable material that creates a more durable and comfortable inflatable. In the industry, TPU is regarded as the material of choice for making the best performance inflatables.

Besides its manufacturing process, TPU also has some significant advantages over PVC including:

- Greater flexibility and excellent strength

- Lighter weight

- Abrasion resistant

- Resistance to oil and solvents

- Resistant to ageing and cracking

- Improved UV resistant.

Due to these advantages and qualities, TPU is already used widely in the manufacturing of other performance products such as snow gear, life-jackets, air-beds, sports equipment and medical products.

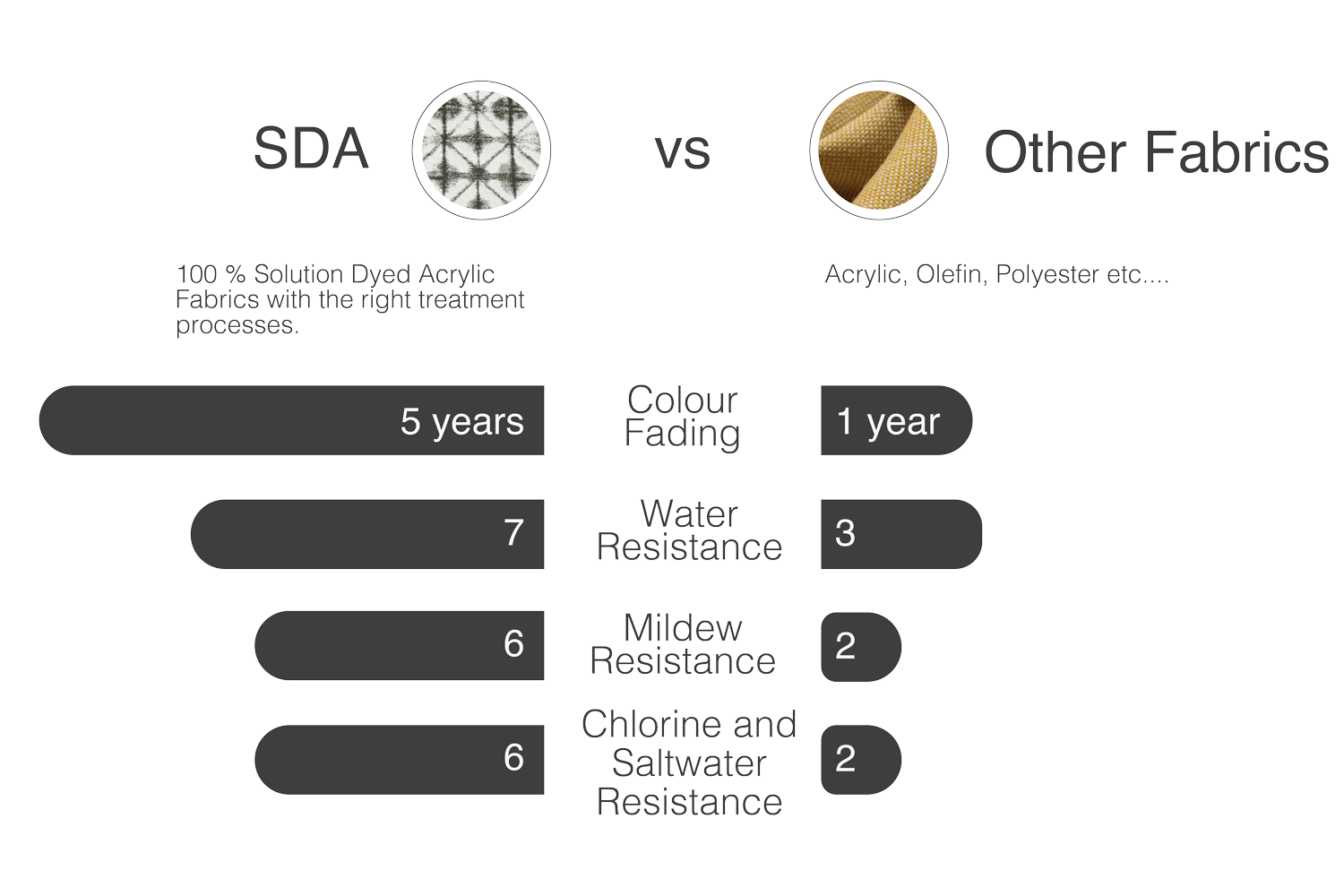

The Alternative, Solution Dyed Acrylic (SDA)

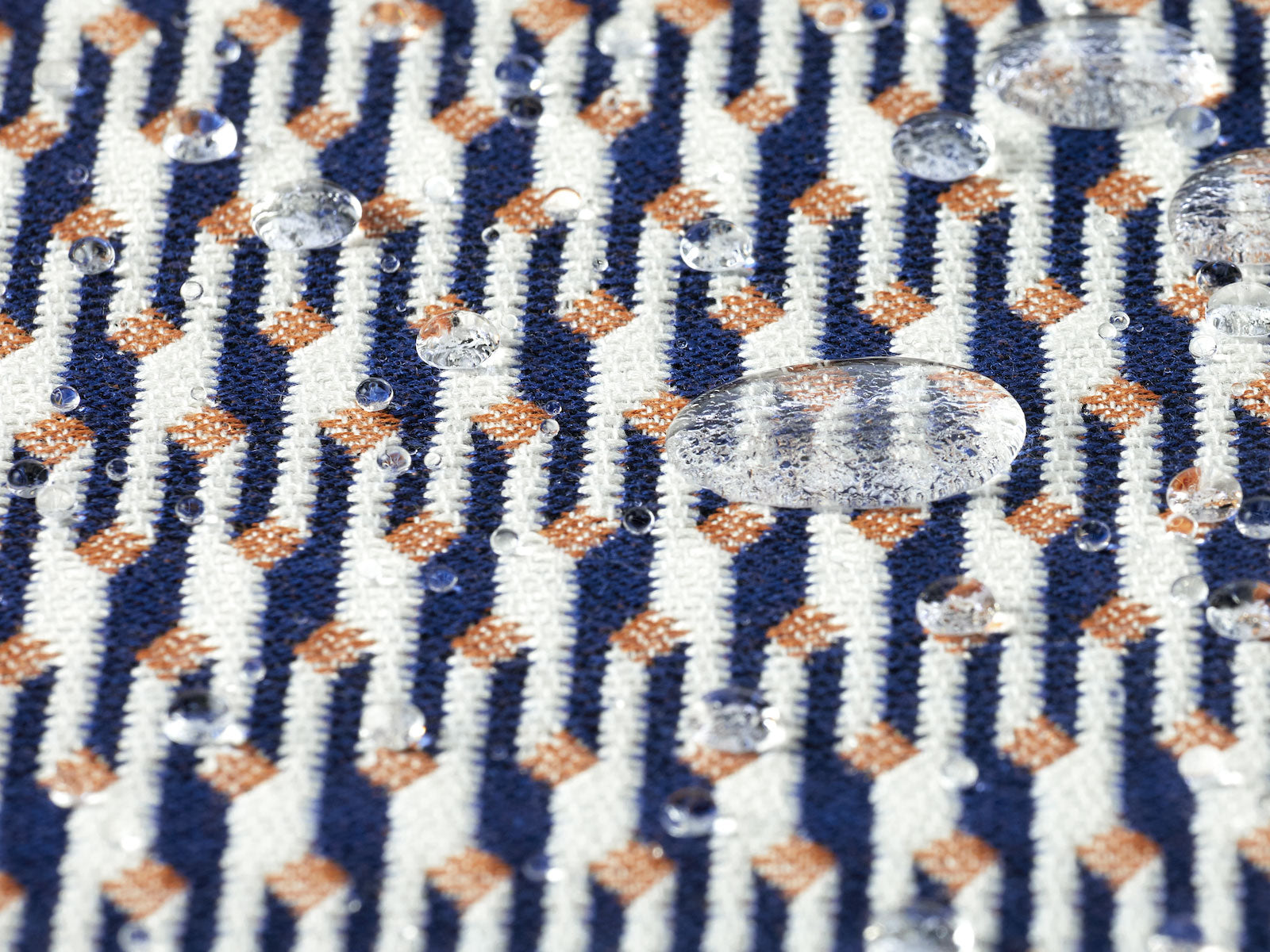

When it comes to our fabrics we work exclusively with partners like Sunbrella, whose products are rooted in sustainability throughout the manufacturing of the fibre, yarn, and fabric. By incorporating the dye into the fibre during the manufacturing process, solution-dyed fabrics reduce water consumption, as they eliminate the need for post-dyeing rinses.

Additionally, the process requires fewer chemicals overall, resulting in reduced chemical usage and environmental impact. The energy requirements for solution dyeing are also lower compared to conventional dyeing methods. These eco-friendly practices help minimise the release of pollutants, conserve resources, and reduce the carbon footprint associated with textile production.

Furthermore, their dedication to quality ensures that you are getting a product that lasts longer, Sunbrella fabrics hold their colour and strength - significantly outlasting traditional fabrics.

At our own manufacturing and assembly facilities, all fabric off-cuts are used to make other products, including fabric swatches, while our collateral and packaging are made of recycled or organic materials and waste material recycled.

We are proud to be working towards a PVC-free inflatable future whilst also giving you the advantage of purchasing a Lilo that is made using the highest quality materials on the market.

Blog posts

On set in Antibes with Anthony Wilson and Jordan Pollak

On set with Anthony Wilson and Jordan Pollak for Oliver James Lilos luxury pool float campaign in Antibes, France.

Your Summer Travel Companion: The Hammock Lilo

Fellow adventurers and luxury connoisseurs, we are thrilled to share some exciting news with you today, as we unveil a product that we have been working on for some time now which is set to be our ...

A luxurious hospitable summer season

We have been both humbled and blessed over the past three years to partner with some of the most renowned boutique hotels and collections from across the globe.